Metal 3D Printing

Possibilities

LINES AND MATERIALS

PLATFORM SIZE

0 x 0 x 0 mm

CONSTRUCTION HEIGHT

zwischen 0–0 mm

RELATIVE DENSITY

0–0 %

BUILDABLE WALL THICKNESS

ab 0 mm

DELIVERED SURFACE ROUGHNESS

Rz 0–0

PLATFORM SIZE

0 x 0 x 0 mm

CONSTRUCTION HEIGHT

zwischen 0–0 mm

RELATIVE DENSITY

0–0 %

BUILDABLE WALL THICKNESS

ab 0 mm

DELIVERED SURFACE ROUGHNESS

Rz 0–0

USE CASES

Technology

LAYER BY LAYER TO THE 3D COMPONENT: METAL

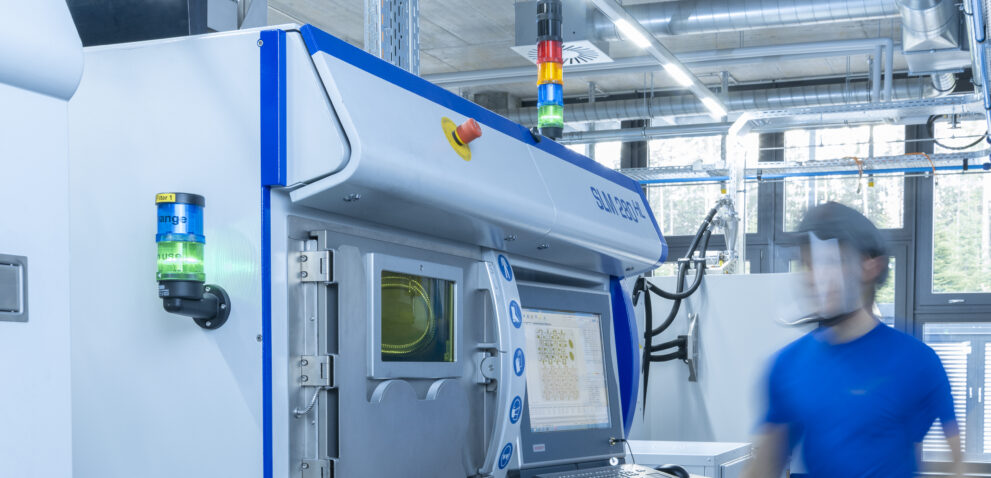

We do our metal 3D printing by selective laser melting or SLM for short. Unlike conventional welding processes, this method uses a laser as the heat source. The welding is done under vacuum for stabilisation purposes.

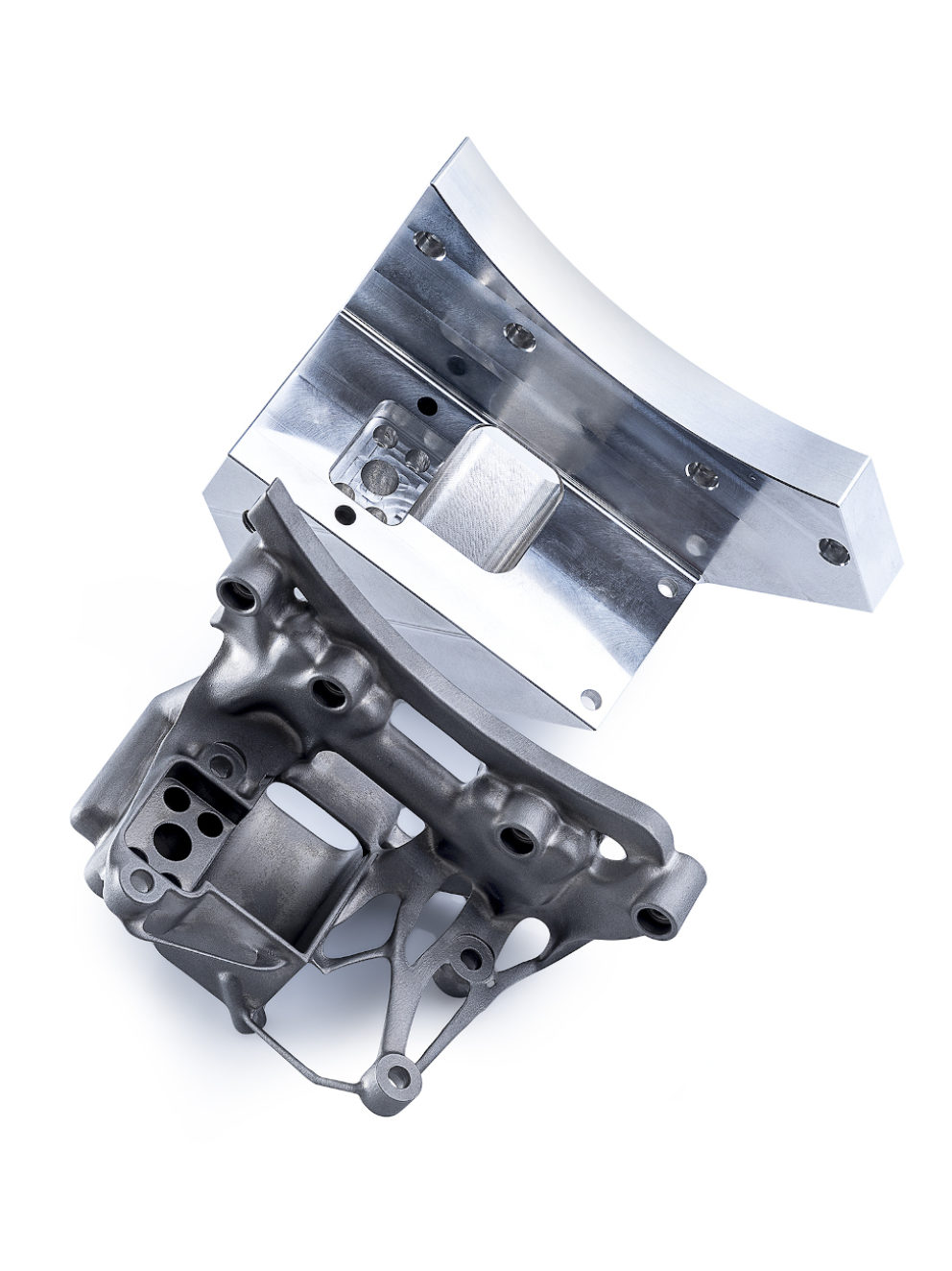

The basic prerequisite is a 3D data set, which gets divided into specific layer information by a slicer in the SLM system based on the thickness of the layers to be built up. After the build platform has been installed in the build chamber, the process can get started. The build plate moves down and the metal powder is evenly distributed so that the laser can burn in the first layer information. This layer becomes welded to a substrate plate, and then the process starts all over again. Once the resulting part has cooled down, it can be removed.

When metals are worked in melting processes, stresses occur in the structure of the components. These then manifest themselves as warping or other undesirable properties. In order to minimise these effects in three-dimensional metal printing, and to homogenise the structure, the additively manufactured metal parts undergo heat treatment. HENNgineered has its own furnace facilities so that we can carry out various annealing processes directly in house.

Following that, the 3D printed metal parts can be reworked using all known metalworking methods. The following processes can be done at HENNgineered for this purpose:

- Blasting

- CNC machining (milling, turning, grinding, eroding, drilling)

- Surface treatment

- Coating

- Hardening