Optimized connections.

Pleasant Flights.

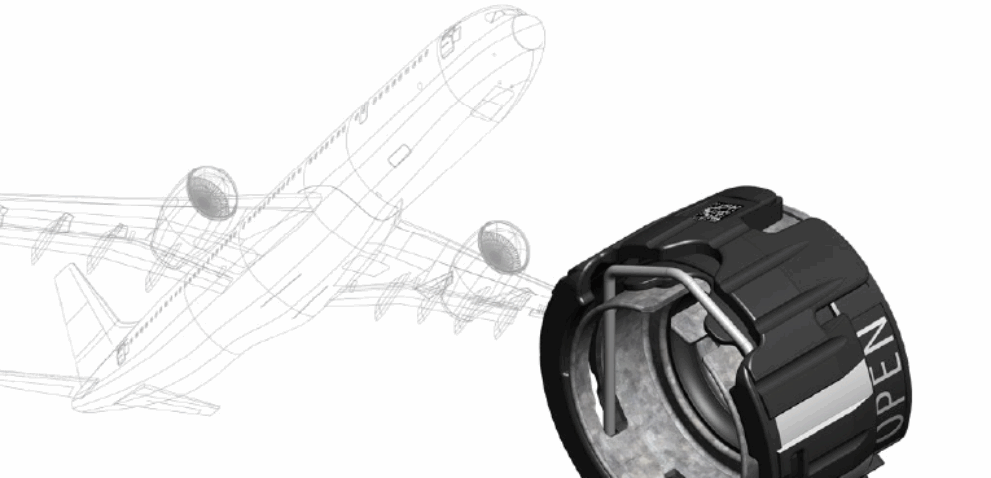

AEROSPACE. HENN in the air.

Aircrafts are only economical when they fly. The time of every MRO (Maintenance Repair Organization) on the ground is tightly timed. This is where our innovative HENN connectors make maintenance easy. They offer perfection down to the smallest detail, absolute reliability and safety without FOD. They are applied to numerous ATA codes, such as Water/Waste, Air-Conditioning and many more.