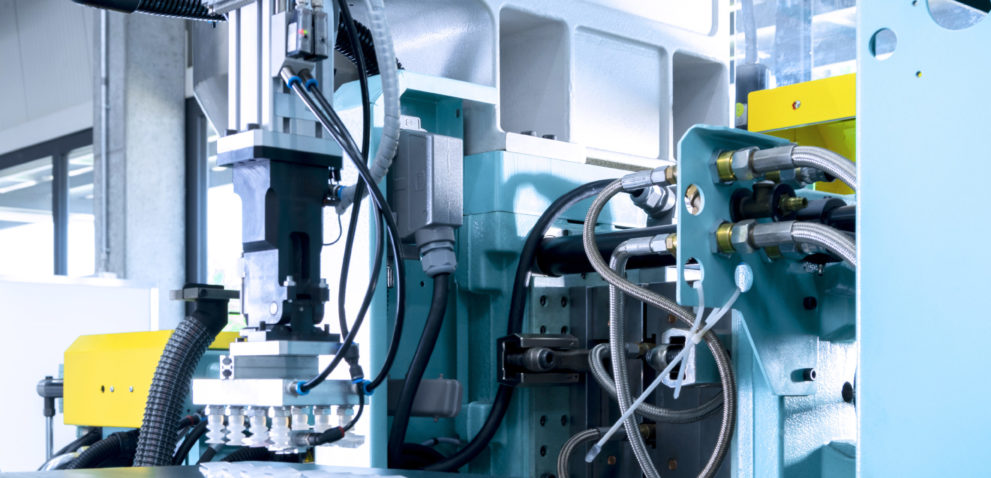

Injection Moulding

Possibilities

EVERYTHING AT A GLANCE

Moulded Part Weight

up to 0 grams

Locking Force

up to 0 tonnes

Quantities

from 0– several million pieces

Tool Temperature

up to 0 ºC

Machines

0 injection moulding machines

Moulded Part Weight

up to 0 grams

Locking Force

up to 0 tonnes

Quantities

from 0– several million pieces

Tool Temperature

up to 0 ºC

Machines

0 injection moulding machines

USE CASES

Technology

GOOD TO KNOW

Plastic injection moulding is a method for producing plastic parts in large quantities. It involves injecting molten plastic into a mould that has the desired shape of the part. The mould consists of two halves that are joined together to form the cavity into which the plastic is injected. After cooling, the mould is opened and the finished part is removed. Plastic injection moulding is a very precise process that allows for high repeatability and fast production. It is used in many industries, such as the automotive industry, electronics and medical technology. The right choice of plastic and mould design are decisive for the quality of the end product.

DO YOU HAVE ANY QUESTIONS?

Loading